2025 Buyer’s Guide to Choosing Custom Binders: Materials, Rings & Finishes

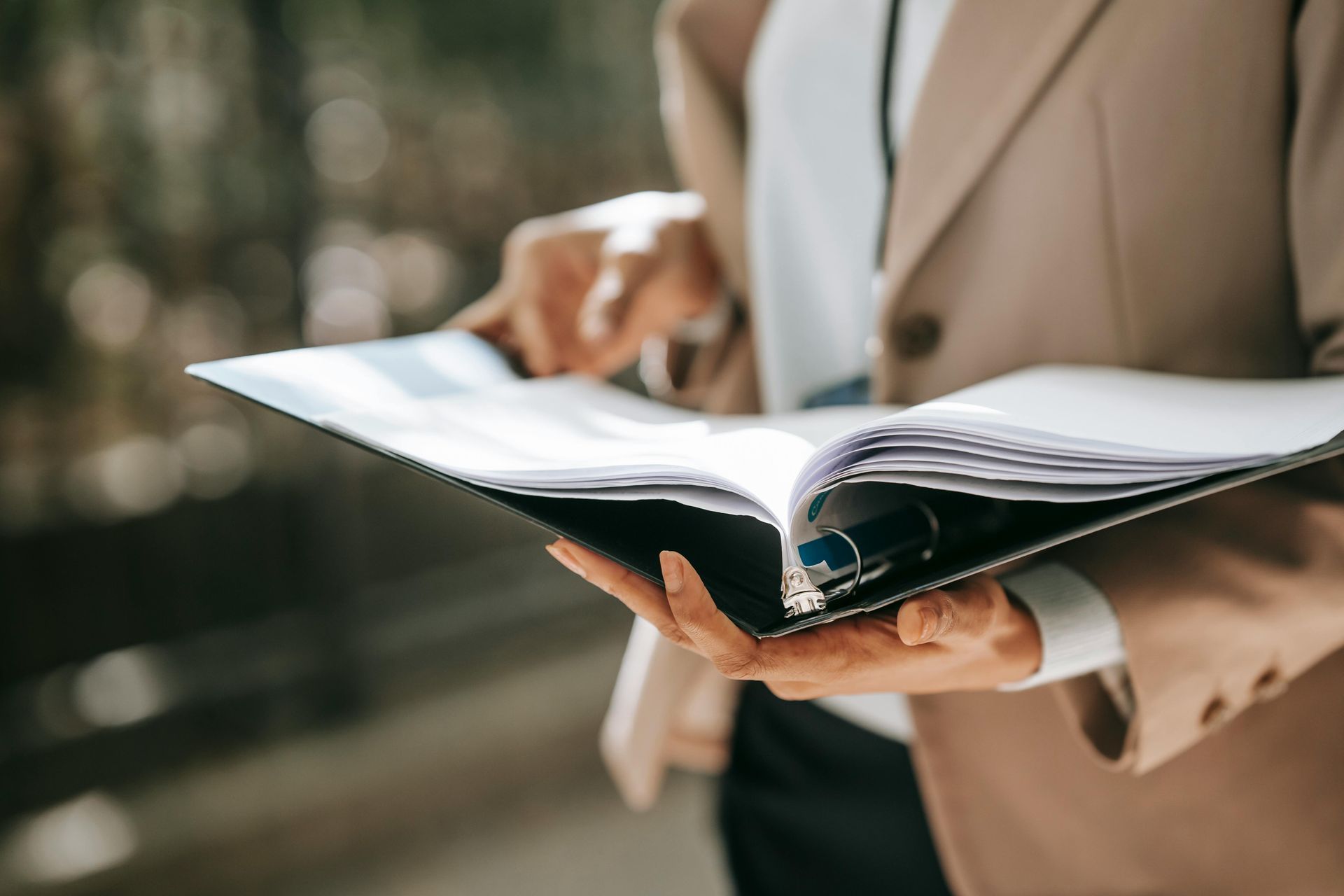

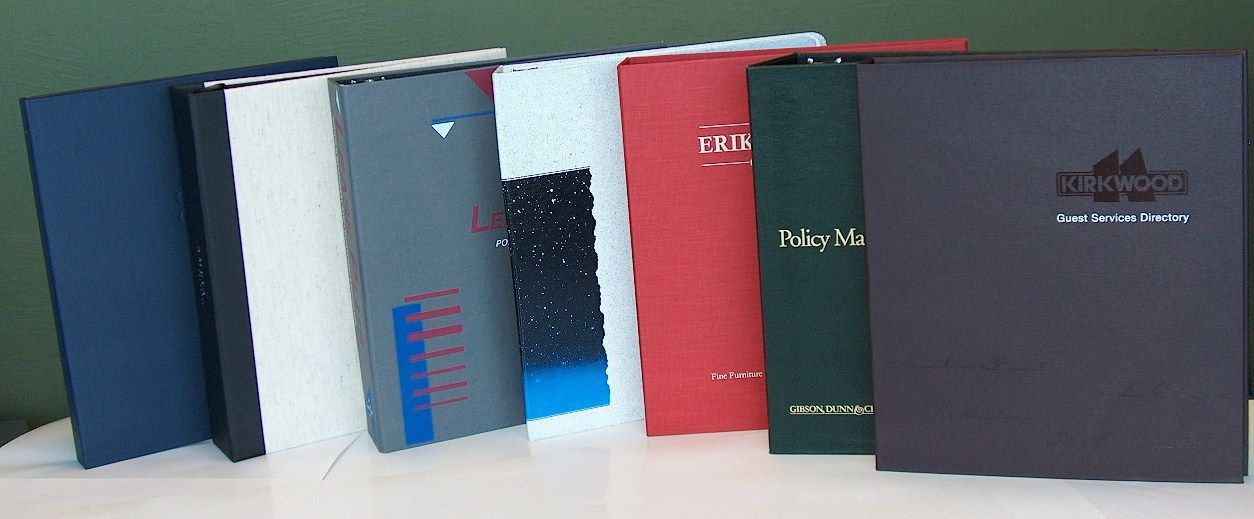

Choosing the right custom binder isn’t as simple as picking a color and adding your logo. Materials, ring mechanisms, branding options, and finishing touches all affect how your binder performs and how it represents your business.

In this definitive 2025 Buyer’s Guide, we’ll cover everything you need to know about binder options, from vinyl vs poly to turned-edge vs paperboard, entrapment vs view binders, ring types, and the finishes that set your brand apart. We’ll also include a comparison table and a simple decision flowchart to help you match binders to your real-world use case.

Start With Your Use Case

Before you look at materials or finishes, ask yourself: What will this binder actually do?

- Training and classroom use → durability is king. Vinyl or poly binders handle heavy turnover.

- Field work or outdoor use → moisture and wear resistance matter most. Poly binders are ideal.

- Executive presentations → luxury look and tactile finishes are critical. Choose turned-edge or stitched.

- Long-term branded kits → permanence is a must. Entrapment binders or slipcases lock in design.

- Flexible updates → marketing materials that change frequently do best in view binders with overlays.

Identifying the purpose upfront makes the next choices clear.

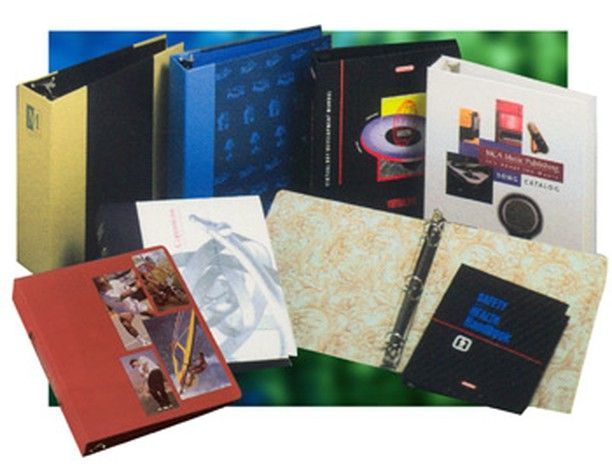

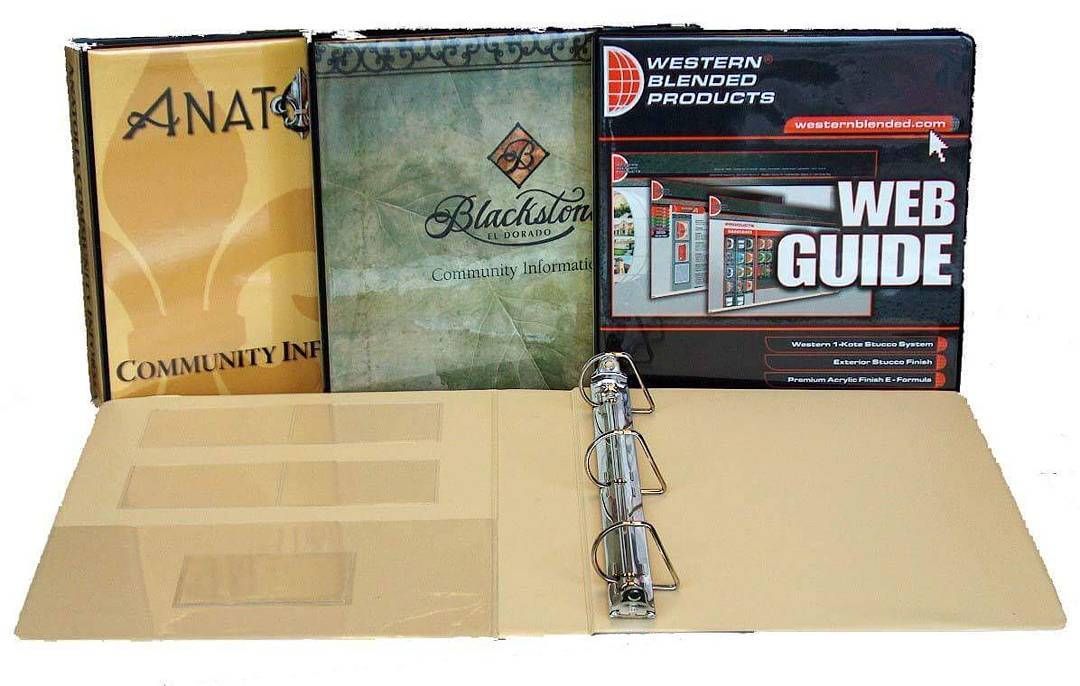

Permanent vs. Flexible Branding

One of the most important decisions is whether you want permanent branding or flexible updates.

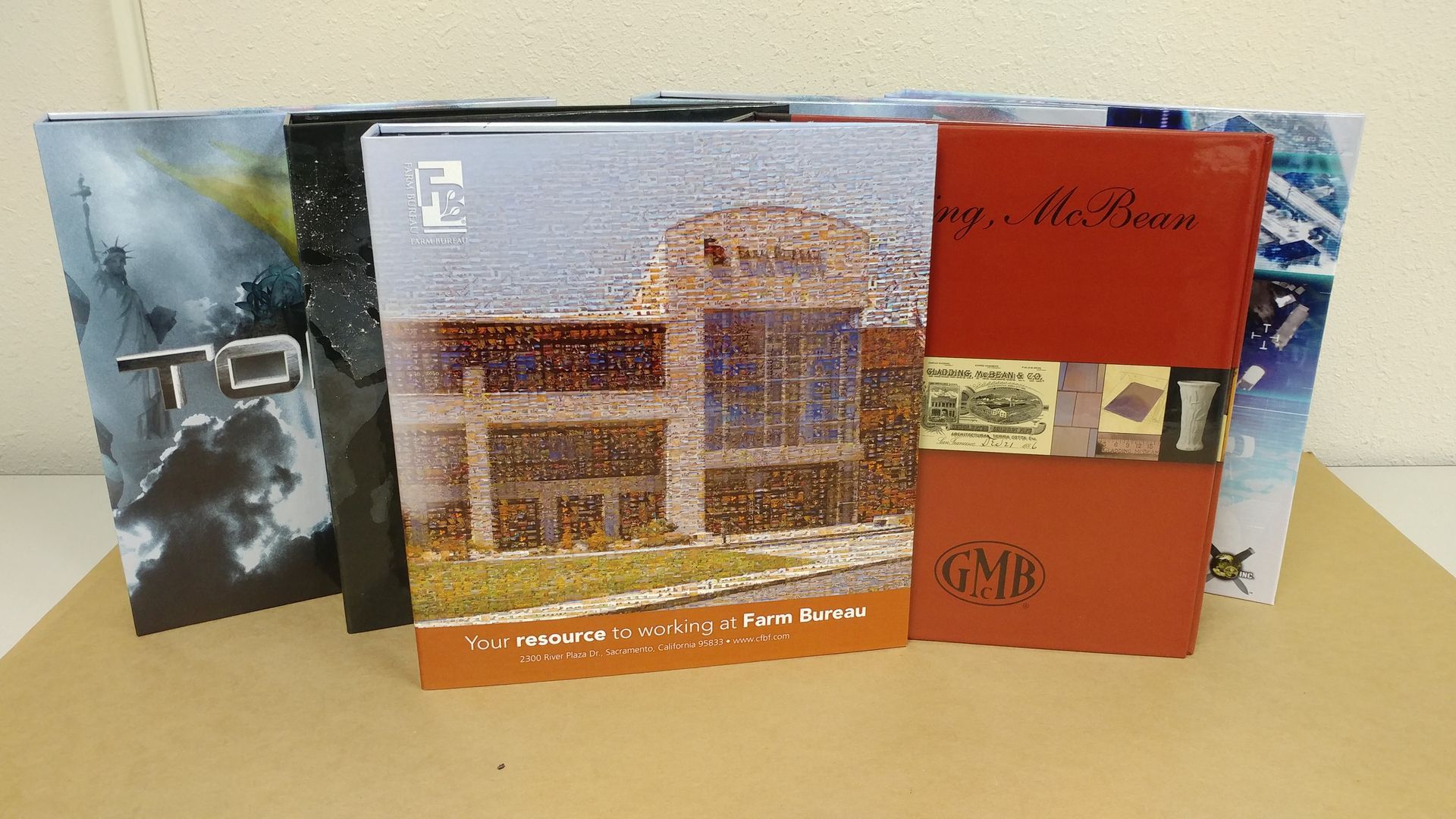

- Entrapment (Embedment) Binders: Printed covers are sealed under clear vinyl. The branding is permanent and professional, with long-term durability. Great for policy manuals, franchise programs, and sales kits that don’t change often.

- View Binders: Clear overlays allow you to slide printed inserts into the front, back, or spine. They’re flexible and budget-friendly, making them ideal for marketing materials, seasonal updates, or temporary campaigns.

Rule of thumb: Use entrapment for a lasting impression, and view binders for short-term flexibility.

Ring Mechanisms & Capacity

Rings may seem like a small detail, but they determine how usable your binder will be day to day.

- Round Ring: Classic style, best for light to medium use. Pages curve when closed. Available in smaller capacities.

- Slant D-Ring: Holds 25–30% more pages than a round ring of the same size. Pages lie flatter, reducing wear.

- Options: Available in sizes from 0.5" to 3", with larger options for high-capacity manuals.

Quick Capacity Guide:

- 0.5" → ~100 sheets

- 1" → ~200 sheets

- 1.5" → ~300 sheets

- 2" → ~400 sheets

- 3" → ~600 sheets

For training manuals or heavy documentation, D-ring wins every time.

Finishes & Branding Options

The finish you choose determines how your binder feels in the hand and how your brand comes across.

- Screen Printing → Best for simple logos on vinyl or poly. Cost-effective and durable.

- Foil Stamping → Metallic accents add elegance; works on vinyl, turned-edge, stitched.

- Embossing/Debossing → Adds texture and dimension to logos; perfect on turned-edge or stitched.

- Spot UV → Glossy highlights over matte backgrounds; works best on turned-edge or laminated paperboard.

- Soft-Touch Lamination → Smooth, upscale feel; popular on turned-edge or paperboard.

Tip: Match your finish to the audience. For example, choose foil/embossing for executive binders and screen printing for field-use binders.

Add-Ons That Change the Experience

Binders don’t have to work alone. Adding matching accessories can turn a basic binder into a full presentation system.

- Slipcases: Protect and present binders as a set; ideal for multi-volume training kits.

- Easel Binders: Self-standing binders for training presentations and sales demos.

- Pad Holders: Great for meetings, conferences, and client giveaways.

- Branded Packaging: Custom boxes or kits that elevate the unboxing experience.

These add-ons can be the difference between a binder that’s “useful” and one that’s memorable.

Quick Decision Flowchart

Here’s a simple flow to help you choose the right binder:

- Will the content change often?

- Yes → View Binder

- No → Continue

- Is durability the top priority?

- Yes → Poly (for field use) or Vinyl (for training)

- No → Continue

- Is executive presentation the goal?

- Yes → Turned-Edge or Stitched Binder

- No → Continue

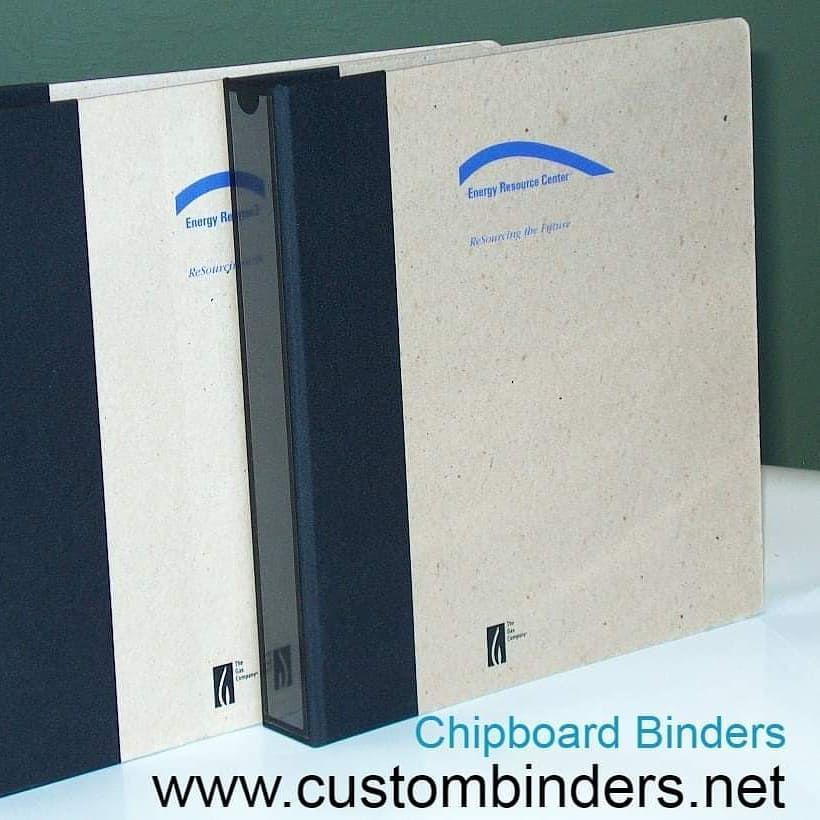

- Do you need eco-friendly or budget-conscious options?

- Yes → Paperboard Binder

- No → Continue

- Is permanent, long-term branding required?

- Yes → Entrapment Binder or Slipcase Set

- No → Vinyl, Poly, or Paperboard depending on use

Pricing, Minimums & Lead Times

Pricing depends on:

- Material (poly is lowest-cost, turned-edge is highest)

- Customization (foil, embossing, or specialty finishes add cost)

- Quantity (higher quantities lower per-unit price)

- Production method (digital vs offset printing)

Lead times:

- Digital short-runs: as fast as 5–7 business days

- Offset/litho runs: typically 2–3 weeks

- Rush service available for many products

For the most accurate pricing, request a custom quote based on your specifications.

FAQs

Are poly binders recyclable?

Yes. Poly binders are made from polypropylene, a recyclable plastic that is both durable and eco-forward.

Will foil stamping work on vinyl binders?

Foil stamping is possible on vinyl, but for crisp, high-end results, turned-edge or stitched binders are better suited.

What ring size do I need?

Use the quick guide above: 1" holds ~200 sheets, 2" holds ~400, and 3" holds ~600.

Conclusion: Choose the Binder That Builds Your Brand

Binders are more than just a way to store paper — they’re a branding tool, a presentation aid, and sometimes the first impression a client gets of your business.

Whether you need durability (poly, vinyl), executive style (turned-edge, stitched), eco-forward value (paperboard), or permanence (entrapment, slipcases), the right binder ensures your message is both protected and elevated.

Ready to create your custom binder?

📞 Call us today: (916) 447-4438

CustomBinders.net – Premium Custom Binders and Presentation Solutions That Make Every Page Count.