Our Manufacturing Process

Our Manufacturing Process – FAQ

1. What are the key steps from quote to delivery?

Our process is designed for precision and efficiency:

- You submit your project specs — binder type, ring size, materials, finishing options, and quantity.

- We send a detailed quote with production timeline.

- After artwork proof approval, we begin production.

- Materials are cut and prepared (board, vinyl, poly, or cover stock).

- Printing or decoration is applied lithograph, screen print, foil, deboss, etc.

- The binder is assembled, inspected, and packaged for shipment.

- Final delivery is coordinated for on-time arrival anywhere in the U.S.

2. What is your standard production time?

Typical turnaround is

15–22 business days after proof approval. Rush orders are available upon request just let us know your deadline.

3.

What materials and finishing options are available?

We offer a wide range of materials and finishes to fit every brand style:

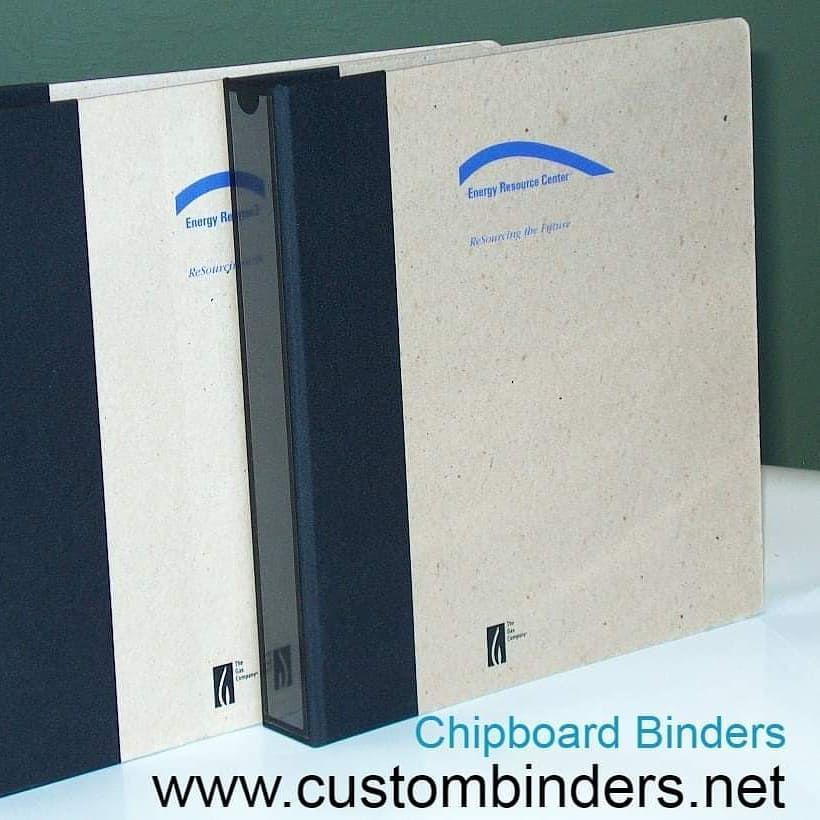

- Materials: turned-edge board, vinyl, poly, chipboard core, and specialty laminates

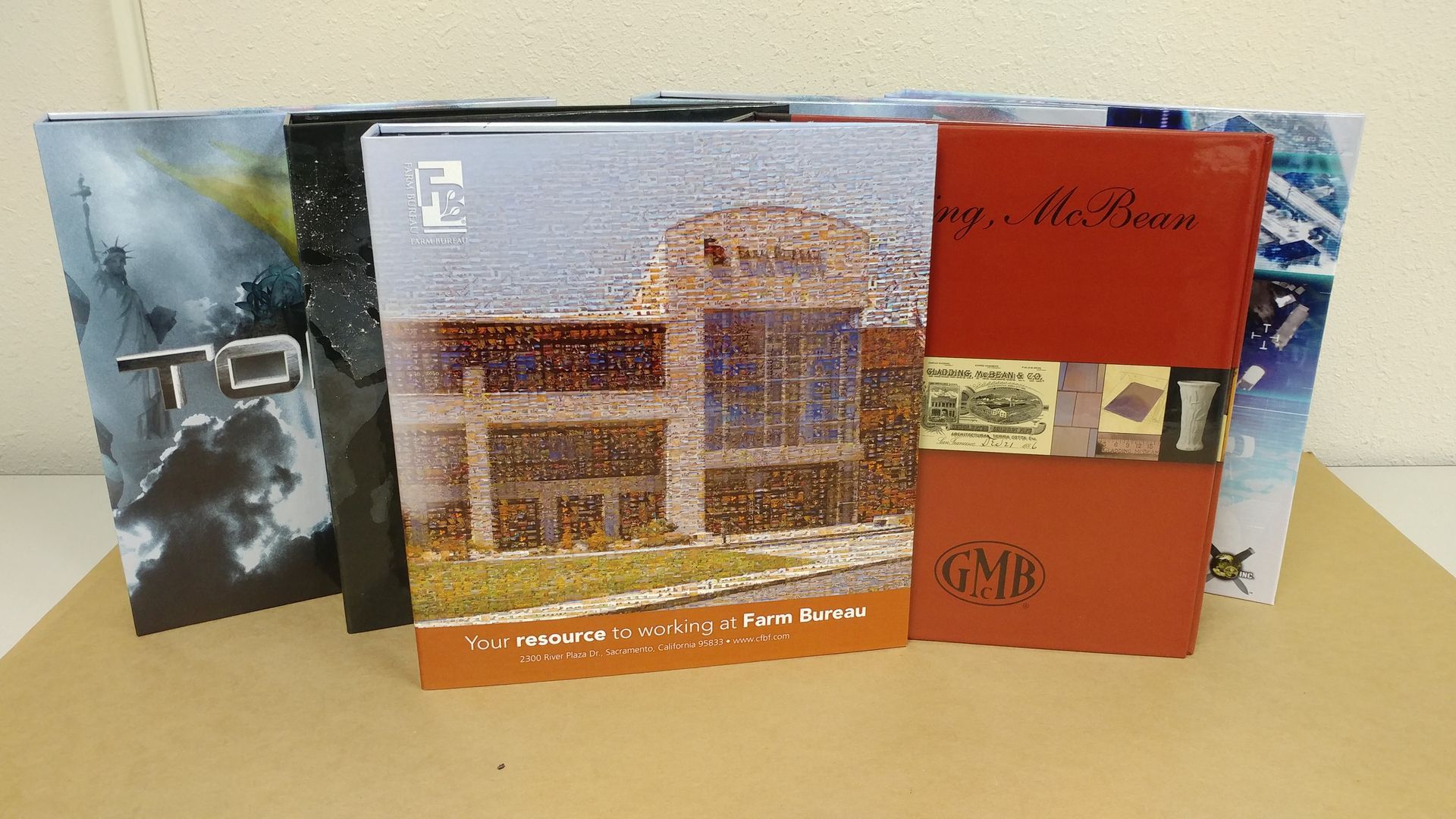

- Finishes: gloss, matte, or soft-touch lamination; foil stamping; embossing or debossing; and full-color lithograph printing

- Ring Styles: round, slant D, and angle D-rings in multiple capacities

4.

How does turned-edge (casemade) construction differ from other styles?

Turned-edge binders wrap printed cover stock around rigid board for a clean, seamless edge. This method delivers a premium “book-like” appearance ideal for presentations, proposals, and sales kits.

5.

How should I prepare artwork and what file formats do you accept?

We accept

print-ready PDF, AI, or EPS files with all fonts outlined or embedded.

- Use CMYK color mode for accurate color reproduction.

- Include 1/4" bleed on all sides.

- Keep key text and logos at least ½″ from trim, rivets, and hinge areas.

We can also assist with layout and file preparation if needed.

6. How do you ensure quality control?

Each order goes through multiple quality checks during material preparation, printing, assembly, and final packaging. Every binder is verified against your approved proof before shipment.

7. Can you produce custom sizes or special features?

Yes. We can manufacture binders in virtually any size with special materials, stitching, die-cuts, or accessories. Our team works closely with you to create one-of-a-kind packaging or presentation solutions.

8. Do you offer fulfillment or drop shipping?

Yes. We can print inserts, tab dividers, or cover sheets, then assemble complete kits and ship directly to your offices, training centers, or event locations. Nationwide fulfillment available.

9. How do I choose the right binder size and ring type?

- ½″ round ring holds roughly 100 sheets (20 lb. bond).

- D-rings hold up to 25% more capacity than round rings of the same size.

- Always leave extra space for inserts or future materials to ensure smooth page turning and a professional fit.

10.

What is your minimum order quantity?

Minimums vary by binder type, but most projects start around

25 pieces. Smaller runs may be possible depending on material and finish contact us for a custom quote.

Custombinders.net Blog Page